Plant Shutdowns are a big deal to management because they have a large economic impact on the company. A Plant Shutdown generally necessitates a period of lost production and is normally a more expensive type of maintenance than routine maintenance. It’s vital to plan shutdowns well, so here are our 10 Golden Rules for a Shutdown Planner.

Note: This post may contain affiliate links. Please read our disclosure policy for more information.

What is a Shutdown?

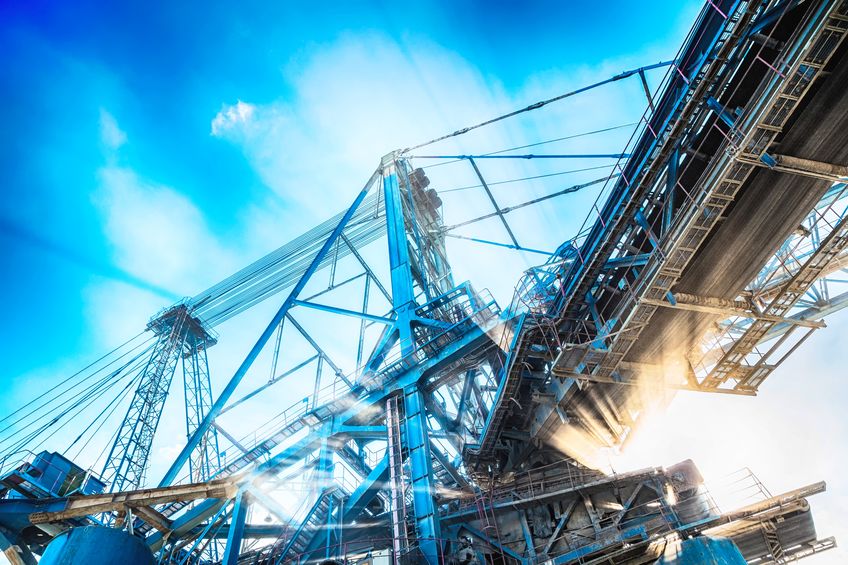

Some people call them shutdowns. Others call them outages. Some industries refer to them as turnarounds. These are all essentially the same thing, under different names. Although you will find that the oil and gas industry prefers to call these events turnarounds, whilst the mining industry prefer to call it a shutdown.

A shutdown is a maintenance event where an entire process plant or unit is taken out of service to perform specific maintenance tasks. That’s because some maintenance tasks cannot be performed unless the entire unit is taken out of service.

The 10 Golden Rules of Shutdown Planning

These are not exactly textbook rules. Rather, they are golden rules that I have learnt through years of front line shutdown planning.

Management Support

It is imperative to get management support for the plant turnaround or shutdown very early. Management must be abundantly clear on the requirement for a plant turnaround, and commit to stopping production for a set period on a set date.

Normally this will be negotiated between production and maintenance management. With a long term maintenance schedule in one hand, and a production forecast in the other, managers must negotiate a long term shutdown schedule well in advance.

After management support is obtained, the date and duration must be locked in. It is important to stick to the committed date, and not allow it to move around. The time wasted by a plant shutdown planning team when a planned shutdown is moved is massive, and should be avoided at all costs.

Shutdown Planning Check Sheet

A detailed shutdown plan will typically have hundreds of tasks for the shutdown planner and scheduler to complete. And there are many interactions with various stakeholders which must be addressed throughout the process. With so many things to remember, no-one in their right mind would attempt to commit these to memory alone.

It is vital to have a rigid shutdown planning process. This must be well documented on a shutdown planning check sheet. There is no need to try to remember all the tasks required, because they are well documented. And the check sheet will also promote better consistency and planning quality.

A typical shutdown check sheet will be broken down into each phase of the shutdown. Under each phase is a long list of tasks, detailing the person responsible, and the due date. The due date is easily calculated by working back a standard number of days from the shutdown date.

A mature shutdown planning check sheet may even incorporate some kind of tracking indicator, to show how well the shutdown planning is tracking. If the planning is falling behind, it’s better to know early so that more resources may be allocated to catch up.

There’s no need to stop there, because a shutdown planning process check sheet is an important tool for a cycle of continual improvement. Each shutdown it should be reviewed, and small tweaks added to make the next shutdown even more successful.

Shutdown Scope Freeze Date

The shutdown scope freeze date may also known as the cut off date. This date must be set to lock the scope of work, such that no new work is accepted. For a 2 or 5-year plant turnaround, this may be 3 months prior to the turnaround.

With shorter interval plant shutdowns, the cut-off date may be reduced. For example, a 6 monthly Total Plant Shutdown may have a cut-off date for new work 6 weeks prior to the shutdown start date.

A company requires a high degree of organisational discipline to stick to a scope freeze date. The date must be well communicated to all stakeholders. And it requires support from the leadership team to enforce the date, and follow a set process when the rules are broken.

Equally important is to have a process in place for work arising after the shutdown cut off date. A Late Work Process requiring approval from management will still allow critical late jobs to be executed, however they must follow a rigid approval process.

Dedicated Shutdown Team

It is important to have a specialized team dedicated to your Plant Shutdown, in both the planning and execution phases. Attempting to share resources between regular maintenance planning and shutdown planning is a big mistake. Shutdown Planning and Scheduling requires 100% focus, and a dedicated team.

The planning phase will of course require the services of at least 1 shutdown planner. It should also have at least 1 shutdown scheduler. Other typical positions are Materials Controller, Technical Writer, Job Scoper, Document Controller and Data Entry Clerk.

The execution phase will require a dedicated Shutdown or Turnaround Manager. Ideally this person will be appointed early in the planning phase of the shutdown. The execution phase also requires a team of dedicated Shutdown Coordinators to bring it all together. There may also be various shutdown support staff like Supervisors, QA, Project Managers, Tool Store personnel, various contractors etc.

Challenge Every Job

Every single job must be challenged to determine if it can be executed outside of the Plant Turnaround. Perhaps the most important Golden Rule of shutdowns planning is “If it can be done outside of a shutdown, it will be done outside of a shutdown“.

A thorough job review should be done from a risk based perspective. This is done in a risk review meeting, where every shutdown job is examined critically. By asking the question “what is the risk of not doing this job”, some jobs may be removed from the shutdown scope. There should be an established method to quantify the risk, and criteria to determine whether the risk is acceptable or not.

Check Every Job Twice

An experienced Shutdown Planner is an extremely valuable asset. Typically they will have many years of technical experience, and capable of fully planning complex shutdown jobs. But every good planner is still prone to make the occasional mistake, or overlook some piece of critical information.

Given the critical nature of shutdowns it is a wise investment to have a second technical resource to double check every shutdown work pack. They should verify that all required resources and materials have been identified. A checklist should be followed, to ensure that nothing is missing form the work pack. And each jobs should be site checked to confirm access and logistic requirements.

Have a Robust Pre Shut and Post Shut Tracking System

Many shutdown jobs require a multitude of pre shutdown tasks completed prior to the shutdown itself. These may range from fabrication of components, refurbishment of components or preparation of the site. It is imperative to have robust system to plan, schedule and track progress on all pre-shutdown tasks.

Normally the CMMS is the best tool for this process. You will need to find some method of coding or filtering all the pre-shutdown tasks to track them. This may be as simple as using a free text string PRESHUT on the individual tasks.

Large shutdowns also have many post shutdown tasks to complete. These may be refurbishing equipment, cleaning up, or returning the work site to it’s original condition. Once again the CMMS is the best tool for this process. It may be as simple as using a free text string POSTSHUT on the individual tasks.

Emergent Work Process

Typically a Late Work Process and an Emergent Work Process are required for Plant Turnarounds.

Late Work is a process to add or remove work from the shutdown schedule, after the cut-off date. This process may require justification and approval by the Turnaround Manager or another Manager.

Emergent Work is a process to add or remove work from the shutdown schedule, after the commencement of the shutdown. This will generally require approval from the Turnaround Manager. It is a reasonable assumption that some emergent or discovery work will be discovered once equipment is opened up during the shutdown.

Shutdown Laydown Area

A successful Plant Shutdown requires a dedicated laydown area for parts and materials to be stored. This must be lockable so it is not raided by the regular maintenance teams during times of parts shortages. It also must be tightly controlled by a Material Controller.

Parts must be well labelled in the shutdown area, with each component being allocated to it’s specific job. Equally important is a robust cataloging system. Each component must be easy to find and manage.

Record Keeping for Shutdowns

Record keeping for shutdowns is required throughout all stages of the shutdown. This includes the planning, execution and post shutdown stages.

In the shutdown planning phase, Shutdown Planners are busy compiling detailed shutdown work packs. These must be tightly controlled so that they are kept intact, and accessible when execution time arrives.

Shutdown execution requires that each Work Pack is issued to a specific person. Records must be kept to indicate who is the custodian of each work pack during shutdown execution.

Post Shutdown requires that each work pack is meticulously filed for historical records. These may be accessed in the future for a variety of reasons. Perhaps it is necessary to interrogate shutdown details of data to assist with planning future shutdowns. Perhaps reliability engineering need to access records. Or perhaps some investigation requires accurate records of events.

Post Shutdown Reviews

An important part of successful shutdowns is building on successes. Another important aspect is learning lessons from past shutdowns, acting on these lessons, and making improvements for future shutdowns. When you think about it, this is consistent with most forms of business.

It is important to collect feedback from a selected group of shutdown participants as soon as possible after the conclusion of the shutdown. This should be in the form of a feedback form. A formal Post Shutdown Meeting is another great method of collecting more feedback.

It is important to act on all approved improvements to the shutdown process. For this reason it’s important to create an action log from the post shutdown meeting. Assign resources to complete each action by a specific due date. And review these actions regularly to ensure they are being done.

Successful Shutdown Planning

Planning a successful Turnaround is all about having a well defined process, and sticking to it. It is also having the ability to adjust the process when valuable lessons are learnt.

These 10 golden rules of shutdown planning are really the tip of the iceberg. I hope they will inspire you to look closer at your processes, and help you towards successful shutdowns.

Learn More about Shutdown Maintenance

There are no secrets to success. It is the result of preparation, hard work, and learning from failure. – Colin Powell

Learning from text books is one key step to enduring success. Here is some recommended reading to help you in your pursuit of excellence.

Would you like a free copy of 7 Steps to Become a KPI Ninja?

Not sure how to set up your Maintenance KPI’s? We have created the 7 Steps to Become a KPI Ninja guide to help you build, analyse and improve your KPI’s. It contains details of all the best metrics to measure, and how to interpret them. And we want you to have it for FREE.